• Moulding at 150˚C using isophthalic resin.

• Moulding under high pressure of 45kgf/cm2 pressure

• Excellent Ultra Violet Resistance characteristics, which doesn’t allow growth of ALGAE or any micro-organisms.

• Strong, with excellent performance and stable construction.

• Uniform shape with good finishing of panels.

• Dense, smooth finish allows effective cleaning and resistance to bacterial growth.

• Suitable for water temperatures upto 50˚C.

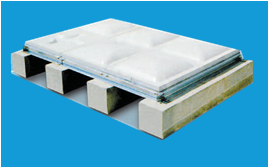

• Specially engineered design of bottom panel to withstand water pressure, prevent water leakage and facilitate easy drainage of water.

• Using Stainless Steel for inside structure and HDG steel for the outside ensures best protection against corrosion.

Rural, semi-urban water supply schemes.

Water supply schemes for housing complexes.

Water storage for firefighting operations.

Water storage in coastal (extremely hot & cold and difficult terrains).

Overhead water storage in multi-storeyed buildings.

On-site water storage & transportation in remote areas.

Water & Wastewater storage in effluent treatment plants.

Water storage in chemical, pharmaceutical and corrosive factory areas.

Hot water storage for solar water heating systems with the help of optional PUF insulation on panels.

Chilled water storage with the Chilling & Air Conditioning plants with the help of PUF insulation on panels.

WhatsApp us